Zone Plates and Custom Options

EUV Zone Plate Specifications

Extreme ultraviolet (EUV) diffractive optics below 120 eV (10-25 nm) are used in applications with EUV lithography, synchrotron microscopes and with high-harmonic generation lab systems. Our products include free-standing resolution/calibration standards, zone plates (blazed and binary), gratings and many other materials. Diffractive optics with ruthienmu

A range of zone plate options for soft/tender X-Rays are available for specific requirements.

EUV Zone Plates

(Custom Designs Available)

| Device | Outer Zone Half-pitch ΔRn (nm) | Thickness (nm) | Outer Diameter (µm) | (# of zones) E/ΔE Limit | ~ Focal Length (µm) | |

|---|---|---|---|---|---|---|

| EUVZP‑200um‑20nm | 20 | 55 | 200 | 2433 | 297 | |

| EUVZP‑300um‑20nm | 20 | 55 | 300 | 3649 | 445 | |

| EUVZP‑350um‑20nm | 20 | 55 | 200 | 2797 | 868 | |

| EUVZP‑200um‑30nm | 30 | 55 | 200 | 1646 | 445 | |

| EUVZP‑300um‑30nm | 30 | 55 | 300 | 2469 | 668 | |

| EUVZP‑350um‑30nm | 30 | 55 | 350 | 2881 | 779 | |

| EUVBZP‑200um‑60nm | 60 | 38+38 | 200 | 831 | 890 | |

| EUVBZP‑300um‑60nm | 60 | 38+38 | 300 | 1246 | 1335 | |

| EUVBZP‑500um‑60nm | 60 | 38+38 | 500 | 2077 | 2225 | |

|

EUVZP (Binary zone plate)

EUVBZP (Blazed (L=3) zone plate) *For estimated efficiency of zone plate, please see our online calculator at www.appliednt.com/zpcalc |

||||||

Soft X-Ray Zone Plate Specifications

X-rays below 5 keV (<~0.25 nm) are typically classified as soft X-rays, where they are more readily absorbed than higher energy X-rays. Typically, zone plates do not require the same thickness for efficiency and allow for higher resolution imaging.

A range of zone plate options for soft/tender X-Rays are available for specific requirements.

Zone Plates

(Custom Designs Available)

| Device | Outer Zone Width ΔRn (nm) | Thickness (µm) | Outer Diameter (µm) | (# of zones) E/ΔE Limit | ~ Focal Length (µm) | |

|---|---|---|---|---|---|---|

| SZP‑90um‑15nm | 15 | <0.07 | 90 | 1514 | 325 | |

| SZP‑120um‑15nm | 120 | 2019 | 433 | |||

| SZP‑200um‑18nm | 18 | <0.15 | 200 | 2797 | 868 | |

| SZP‑270um‑18nm | 270 | 3775 | 1172 | |||

| SZP‑320um‑18nm | 320 | 4473 | 1389 | |||

| SZP-200um-25nm | 25 | <0.24 | 200 | 2007 | 1207 | |

| SZP‑250um‑25nm | 250 | 2509 | 1510 | |||

| SZP-300um-25nm | 300 | 3010 | 1811 | |||

| SZP-360um-25nm | 360 | 3612 | 2173 | |||

| TZP‑160um‑50nm | 50 | <0.75 | 160 | 801 | 1934 | |

| TZP‑280um‑50nm | 280 | 1401 | 3384 | |||

| TZP‑750um‑200nm | 200 | <0.75 | 750 | 938 | 36292 | |

| TZP‑1250um‑200nm | 1250 | 1563 | 60487 | |||

| *For estimated efficiency of zone plate, please see our online calculator at www.appliednt.com/zpcalc | ||||||

Hard X-Ray Zone Plate Specifications

X-Rays above 5-10 keV transition from tender to hard X-Rays where they are better able to penetrate through samples to give better imaging. Hard X-ray Fresnel zone plates require high aspect ratio features to offer sufficient efficiency and resolution for energies above 5 keV. Our current optics give ultra-high resolution for sub 25 nm – 100 nm imaging depending on the required energy. Stacking of hard X-rays (either through double processing or chip alignment) can significantly increase the efficiency of our devices.

A range of zone plate options for hard X-Rays are available for specific requirements.

Zone Plates

(Custom Designs Available)

| Device | Outer Zone Half-Pitch ΔRn (nm) | Thickness (µm) | Outer Diameter (µm) | (# of zones) E/ΔE Limit | Energy Range (keV) | |

|---|---|---|---|---|---|---|

| HZP-50-25nm | 25 | >0.65 | 50 | 500 | 1.5 to 10 | |

| HZP-75-25nm | 75 | 750 | ||||

| HZP‑100um‑42.5nm | 42.5 | >0.8 | 100 | 588 | 2 to 12 | |

| HZP‑85um‑50nm | 50 | >0.9 | 85 | 425 | 2 to 12 | |

| HZPSC/HZPX‑85um‑50nm | >1.5 | 5.5 to 20 | ||||

| HZP‑180um‑50nm | >0.9 | 180 | 900 | 2 to 12 | ||

| HZP‑550um‑50nm | >0.9 | 550 | 2750 | 2 to 12 | ||

| HZPSC/HZPX‑550um‑50nm | >1.5 | 5.5 to 20 | ||||

| HZP-400um-100nm | 100 | >1.8 | 400 | 1000 | 2.5 to 8 | |

| HZPSC/HZPX‑400um‑100nm | >2.5 | 8 to 30 | ||||

| HZP‑400um‑120nm | 120 | >2.0 | 400 | 834 | 5 to 25 | |

| HZPSC/HZPX‑400um‑120nm | >2.6 | 8 to 30 | ||||

| HZP‑750um‑200nm | 200 | >2.2 | 750 | 938 | 7 to 20 | |

| HZPSC/HZPX‑750um‑200nm | 200 | >3.6 | 12 to 50 | |||

| *For estimated efficiency of zone plate, please see generated graphs below or download our zone plate software. All zone plate diameters can be customized for specific setups. Standard frame sizes are 5 mm x 5 mm with SiC or SiN membranes (1000 nm). HZP - Standard Binary Zone Plate HZPSC - Staircase Zone Plate HZPX - 2x Thickness, similar to the staircase, but binary design. |

||||||

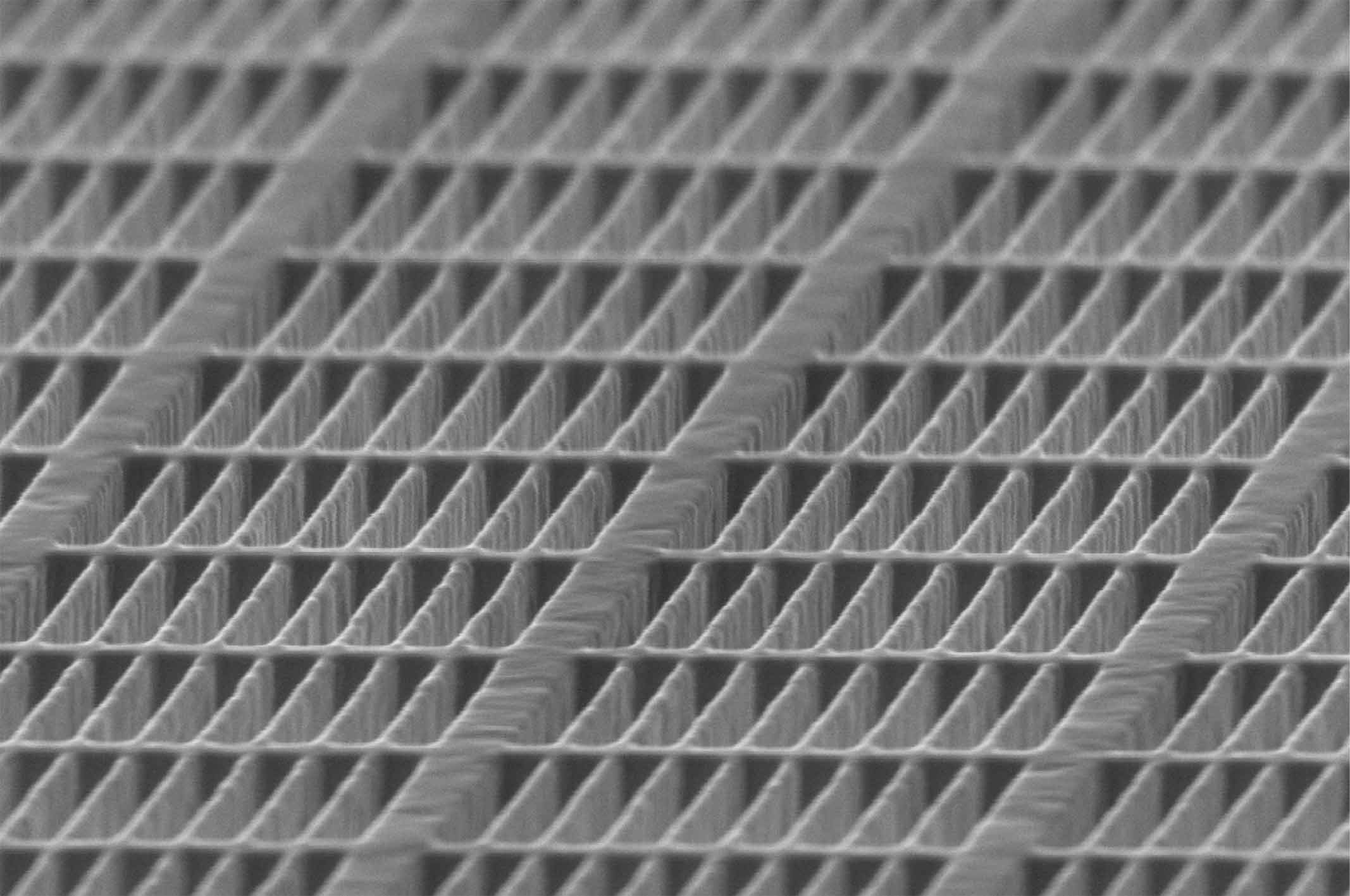

Oxide Interlock Process for Hard X-Ray Optics

Zone plate efficiency for binary zone plates requires high aspect ratio structures which can survive high flux imaging systems. The “Oxide Interlock” option creates small interconnecting channels between metal zone of silicon dioxide which is transparent to hard X-rays and does not swell or distort, even when not under vacuum. These have been shown to significantly increase the zone plate efficiency and lifetime.

Zone Plate Materials

We offer a range of different materials, all chosen to provide the maximum resolution and efficiency for different energies. We currently offer as different materials for zone plates: Au, Cu, Mo, Ni, W, Pt, and free-standing silicon nitride. To compare the different materials, see our zone plate calculator at www.appliednt.com/zpcalc

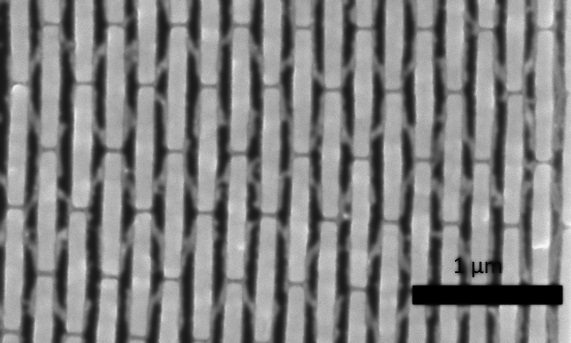

Copper zone plate with 250 µm diameter and 80 nm outer zones

SEM image of copper zone plate with 250 µm diameter and 25 nm outer zones

Central Stops and Outer Blockers

Central stop and outer blocker options significantly improve zone plate imaging, with reduction of the 0th order and improved lifetime of the optics. Various Thicknesses up to 3 µm on chip are available or >10 µm as a separate chip.

Custom Designs and Frame Sizes

Custom designs and frame sizes can be developed for specific applications. We are able to fabricate devices down to 1 mm (image right shows 1 mm x 3 mm frame as smallest size). Our standard frame sizes are 3, 5, 8 and 10 mm in width/heigh and membrane thicknesses from 50 to 2000 nm (Si, SiC and SiNx).

XY Stage for Zone Plate/ Central Stop Alignment

Our custom XY stage allows micro-scale alignment of a central stop and zone plate and also allows for a possible blast-shield to be mounted. The outer dimensions of the XY stage are 19 mm wide x 19 mm tall x 5.1 mm deep and is made of lightweight aluminum. Threaded M2 screw holes are provided for straightforward attachment to any existing experimental setups.